Advanced testing for unmatched quality

Elevating quality with cutting-edge testing techniques

Our Quality Policy

At Yathartha, our commitment to quality is at the core of everything we do. We adhere to rigorous standards and continuously improve our processes to ensure the production of reliable, high-performance fasteners.

Testing at Yathartha

Our advanced lab facility is equipped with cutting-edge testing technology to ensure top-tier fastener quality. We conduct rigorous tests, including tensile, hardness, and corrosion resistance, to meet industry standards.

CORROSION TESTING

We assess the fasteners' resistance to corrosion through salt spray tests. This is especially important for fasteners used in harsh environments.

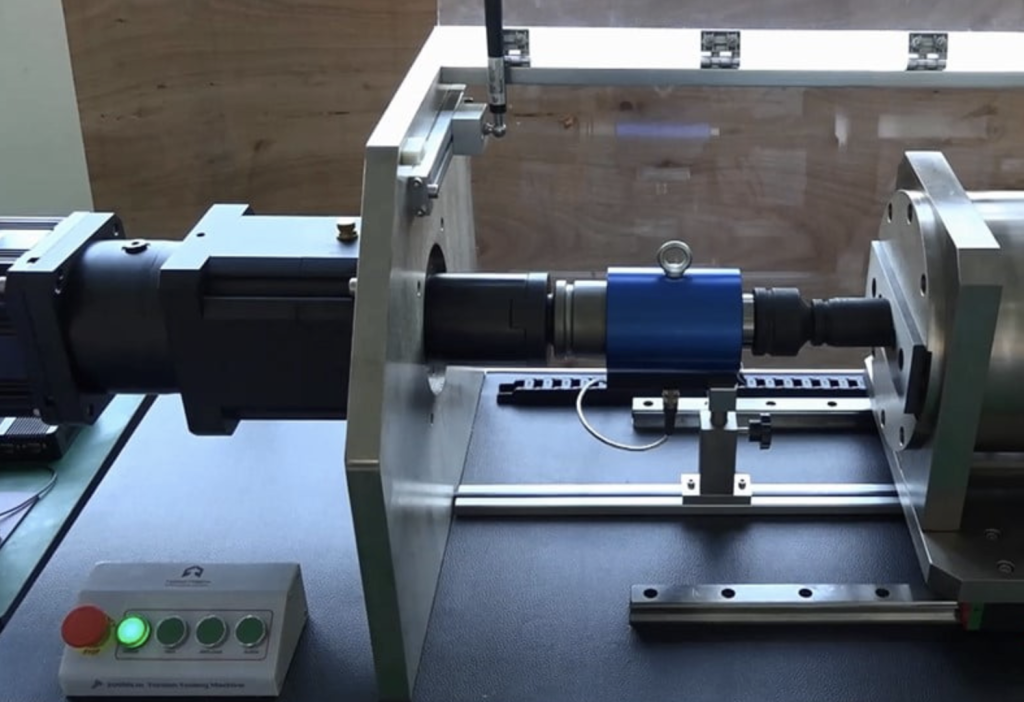

TORQUE TESTING

Determine the relationship between the torque applied to a fastener and the resulting tension or clamping force. This helps ensure proper fastening and preload in applications.

TENSILE STRENGTH TESTING

To test a fastener's tensile strength, a wedge is placed under the fastener's head and force is applied until it breaks. The wedge is used to put extra stress on the junction of the fastener's head and body.

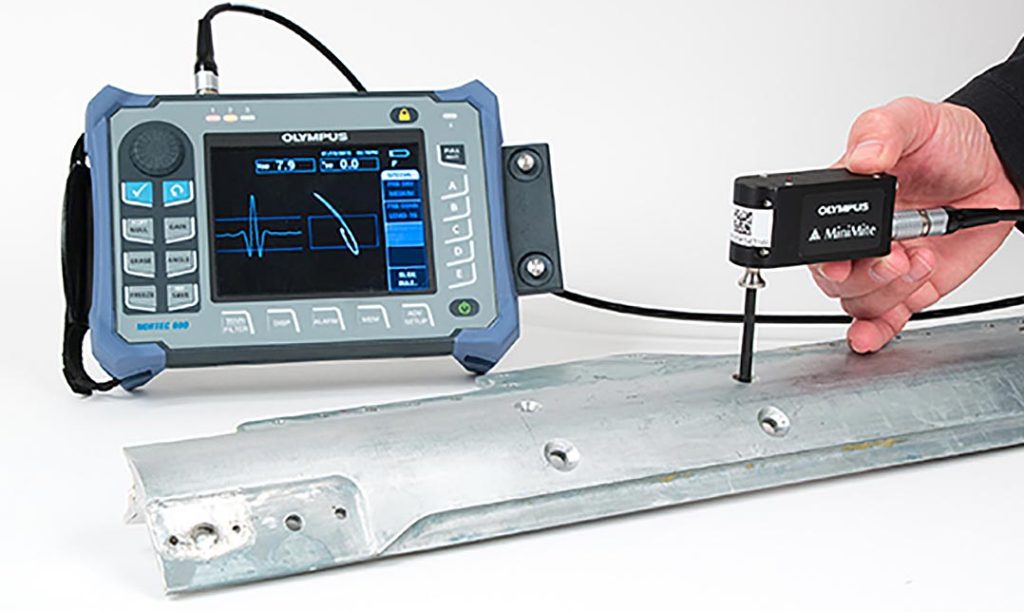

METALLURICAL TESTING

Metallurgical testing can be destructive or non-destructive. Microscopes are used in metallurgical testing to provide details about the structure and properties of the sample.

CHEMICAL TESTING

If the start material or semi-finished fastener bears the right chemistry, there is every chance that optimum subsequent downstream processing will result in specification compliance.

HARDNESS TESTING

A precisely defined force is applied to the fastener with a uniquely shaped indenter to create an indentation. The depth of the indentation is measured and used to calculate the hardness.

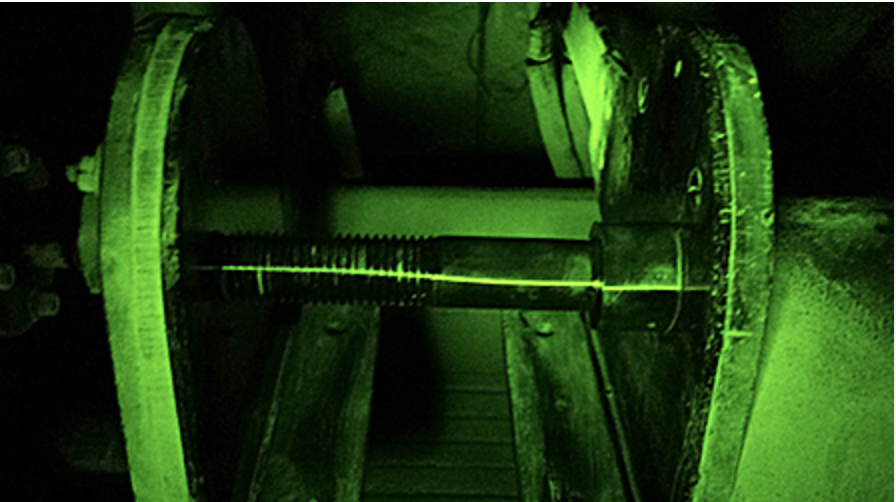

EDDY CURRENT TESTING

A coil energized by alternating current is placed near the test surface, creating an alternating magnetic field. This field induces eddy currents in the test piece, and changes in the eddy currents are measured to identify defects.

OPTICAL SORTING

Optical sorting achieves non-destructive, 100 percent inspection in-line at full production volumes. In general, optical sorters feature four major components: the feed system, the optical system, image processing software, and the separation system.